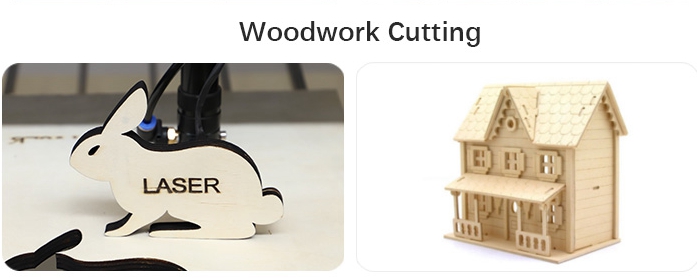

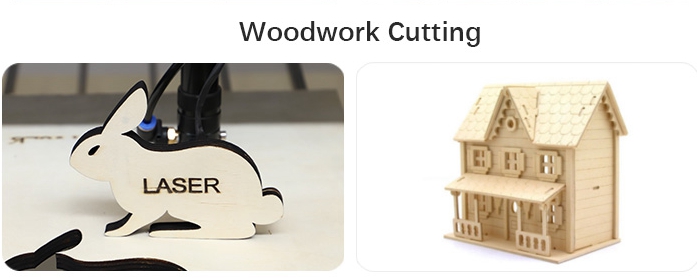

Wood Laser Cutter: Precision and Efficiency in Woodworking

Woodworking has been revolutionized by the introduction of advanced tools and technologies. One such technology that has gained significant popularity in recent years is the wood laser cutter. A wood laser cutter utilizes a high-powered laser beam to cut and engrave wood with remarkable precision and efficiency. This cutting-edge tool offers numerous advantages over traditional woodworking methods, making it a valuable asset for craftsmen, hobbyists, and industries alike.

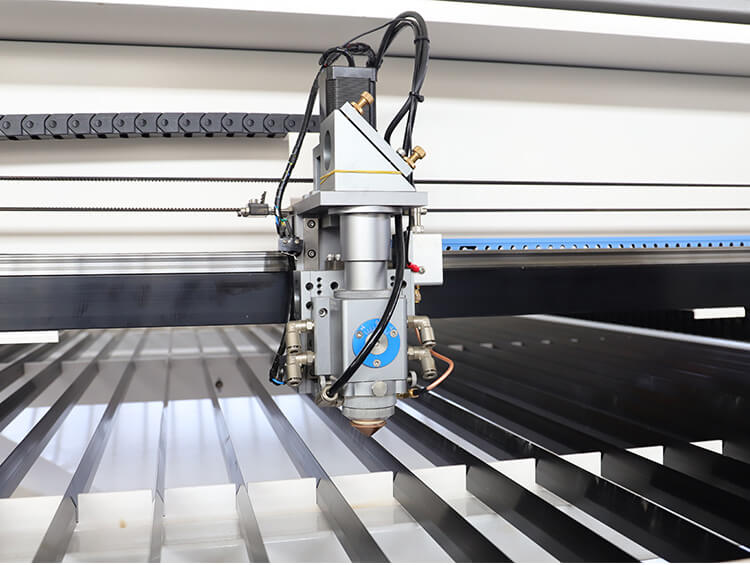

Wood laser cutter is a type of cutting machine that uses a high-powered laser beam to cut through wood. The laser beam is typically generated by a CO2 laser, which is focused through a series of mirrors and lenses onto the wood to be cut.

Advantages of Wood Laser Cutter:

Precision: The wood laser cutter provides unparalleled precision in cutting and engraving wood. The laser beam can be controlled with utmost accuracy, resulting in clean and intricate cuts. This level of precision allows for the creation of intricate designs, delicate patterns, and precise joints.

Efficiency: The laser cutting process is exceptionally fast and efficient compared to conventional methods. The wood laser cutter operates with high speeds, reducing production time significantly. It can swiftly cut through wood, creating finished pieces in a fraction of the time required by manual cutting techniques.

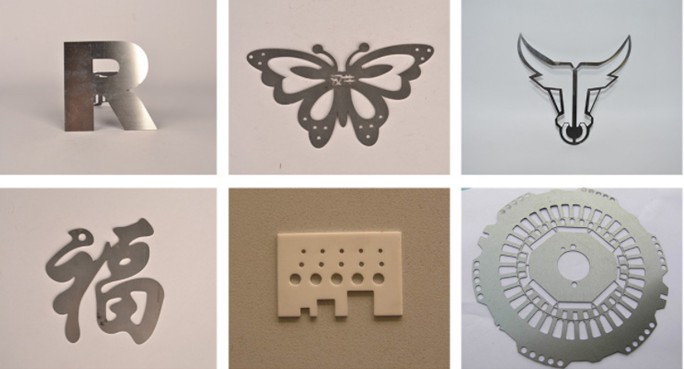

Versatility: Wood laser cutters offer remarkable versatility in terms of design possibilities. They can cut and engrave a wide range of wood types, including plywood, hardwood, MDF, and more. This flexibility enables users to create diverse products, including furniture, decorative items, architectural elements, signage, and personalized crafts.

Minimized Material Waste: With precise laser cutting, the wood laser cutter minimizes material waste. The narrow laser beam allows for tight nesting of designs, maximizing the usage of the wood sheet. This reduction in waste not only saves costs but also promotes sustainability by utilizing resources more efficiently.

Automation and Repetition: Wood laser cutters can be programmed to repeat designs and cutouts, ensuring consistent results. This automation feature eliminates human errors and ensures uniformity in the produced pieces. It also enables efficient batch production, making it ideal for industries with high-volume manufacturing needs.

Applications of Wood Laser Cutter:

Wood laser cutters are used in a variety of industries, including woodworking, furniture manufacturing, and crafts. They are often used to cut intricate designs and shapes that would be difficult or impossible to create by hand or with traditional cutting tools. However, it is important to note that wood laser cutting can generate smoke and fumes, so proper ventilation and safety precautions are necessary.

Furniture Manufacturing: Wood laser cutters are extensively used in the production of furniture, including chairs, tables, cabinets, and shelves. They can accurately cut intricate patterns, decorative elements, and joinery details, adding a touch of uniqueness to each piece.

Architectural Woodwork: Wood laser cutters are employed in architectural woodworking to create intricate wood panels, wall partitions, ceiling tiles, and decorative screens. They can produce intricate designs that enhance the visual appeal of interior spaces.

Crafts and Decorative Items: Wood laser cutters are widely used in the creation of crafts and decorative items. They can engrave intricate designs, personalization, and delicate patterns on wooden plaques, coasters, ornaments, and gift items.

Signage and Branding: The precision of a wood laser cutter makes it an excellent tool for creating custom signage and branding elements. It can engrave logos, texts, and graphics on wooden boards, nameplates, and promotional items.

Model Making and Prototyping: Wood laser cutters are invaluable for model making and prototyping purposes. They can accurately cut and engrave wood to create architectural models, product prototypes, and scale models with intricate details.

The laser beam vaporizes the wood at the point of contact, creating a narrow cut that is typically very precise. The width of the cut can be adjusted by changing the focus of the laser beam, and the speed of the cut can be controlled by adjusting the power of the laser.

Wood laser cutter can be used to cut and engrave a wide range of woods, including hardwoods, softwoods, plywood, and MDF (medium-density fiberboard). They can also be used to cut through other materials, such as acrylic, leather, and certain types of plastics.

One of the advantages of using a wood laser cutter is its high level of precision. The laser beam can be programmed to cut intricate designs with very fine details, making it ideal for creating decorative items, signage, and other specialized products. In addition, the cut edges of the wood are typically very clean and smooth, requiring little or no post-processing.

Wood laser cutter come in a range of sizes and power levels, depending on the specific needs of the user. Small desktop models are available for hobbyists and small businesses, while larger industrial models are used in large-scale manufacturing operations.

CNC Laser Cutting Engraving Machine for Acrylic Wood Metal

CNC laser cutting and engraving machine can be used for cutting and engraving a variety of materials, including acrylic, wood, and metal. These machines use a laser to cut and engrave materials based on a pre-programmed design.

When choosing a CNC laser cutting and engraving machine for these materials, it’s important to consider factors such as the power of the laser, the size of the machine, the type of laser (CO2 or fiber), and the software used to program and control the machine.

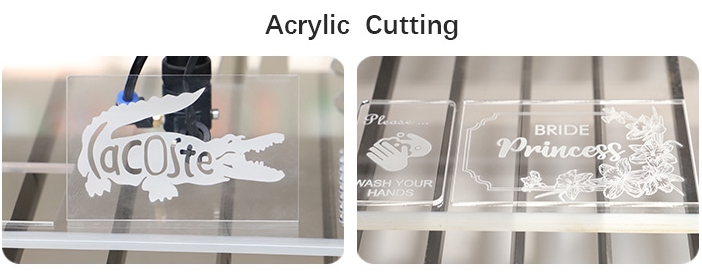

Acrylic is a popular material for laser cutting and engraving, as it can be easily cut and engraved to create intricate designs. Wood is also a popular material, and can be engraved to create personalized signs, plaques, and other decorative items. Metal can be cut and engraved using a fiber laser, which is more powerful and can cut through thicker materials than a CO2 laser.

CNC Laser Cutting Engraving Machines have revolutionized the world of manufacturing and craftsmanship, offering precise and efficient solutions for cutting and engraving a wide range of materials. This article explores the advantages and applications of CNC Laser Cutting Engraving Machines, with a particular focus on their capabilities in working with acrylic, wood, and metal. From intricate designs to industrial applications, these machines deliver exceptional precision and versatility, empowering users to bring their visions to life.

Advantages of CNC Laser Cutting Engraving Machines:

Precision and Accuracy: CNC Laser Cutting Engraving Machine employ high-powered lasers controlled by computer systems, ensuring unparalleled precision and accuracy. They can execute intricate designs with fine details, delivering consistent results every time.

Versatility in Material Compatibility: These machines are capable of working with various materials, including acrylic, wood, and metal. They offer the flexibility to switch between different materials seamlessly, making them suitable for a wide range of applications.

Efficiency and Time Savings: CNC Laser Cutting Engraving Machines significantly reduce production time and labor costs. Their high cutting and engraving speeds, combined with automated processes, enable faster project completion and increased productivity.

Minimal Material Waste: The precision of laser cutting reduces material waste to a minimum. By optimizing the cutting path and minimizing kerf width, CNC Laser Cutting Engraving Machines maximize material utilization, resulting in cost savings and a more sustainable production process.

Non-Contact Process: Laser cutting and engraving are non-contact processes, eliminating the need for physical force or mechanical pressure on the material. This feature prevents potential damage to delicate or fragile materials, ensuring a clean and precise outcome.

Customization and Personalization: CNC Laser Cutting Engraving Machines allow for easy customization and personalization of designs. Whether it’s engraving names, logos, or intricate patterns, these machines offer the flexibility to create unique and tailored products.

Applications of CNC Laser Cutting Engraving Machines:

Acrylic Fabrication: CNC Laser Cutting Engraving Machines excel in cutting and engraving acrylic materials. They are widely used in the fabrication of signage, displays, decorative panels, and architectural elements. The precise cutting and clean edges achieved by these machines enhance the aesthetic appeal of acrylic products.

Woodworking: CNC Laser Cutting Engraving Machines are valuable tools in the woodworking industry. They can intricately cut and engrave wood materials, producing decorative panels, customized furniture components, intricate patterns, and personalized wooden products.

Metal Fabrication: CNC Laser Cutting Engraving Machines are capable of cutting and engraving various types of metal, including stainless steel, aluminum, and brass. They find applications in metal fabrication industries, such as sheet metal cutting, jewelry making, and custom metal signage production.

Packaging and Prototyping: CNC Laser Cutting Engraving Machines are widely used in the packaging industry to create precise and customized packaging designs. They are also employed in prototyping processes, allowing designers and engineers to quickly iterate and refine their designs.

Personalized Gifts and Awards: These machines enable the creation of personalized gifts and awards, such as engraved plaques, trophies, and customized promotional items. The high level of detail and customization options offered by CNC Laser Cutting Engraving Machines add a unique touch to these special items.

CNC Laser Cutting Engraving Machines have revolutionized the world of manufacturing and craftsmanship, offering precise and efficient solutions for cutting and engraving a wide range of materials. This article explores the advantages and applications of CNC Laser Cutting Engraving Machines, with a particular focus on their capabilities in working with acrylic, wood, and metal. From intricate designs to industrial applications, these machines deliver exceptional precision and versatility, empowering users to bring their visions to life.