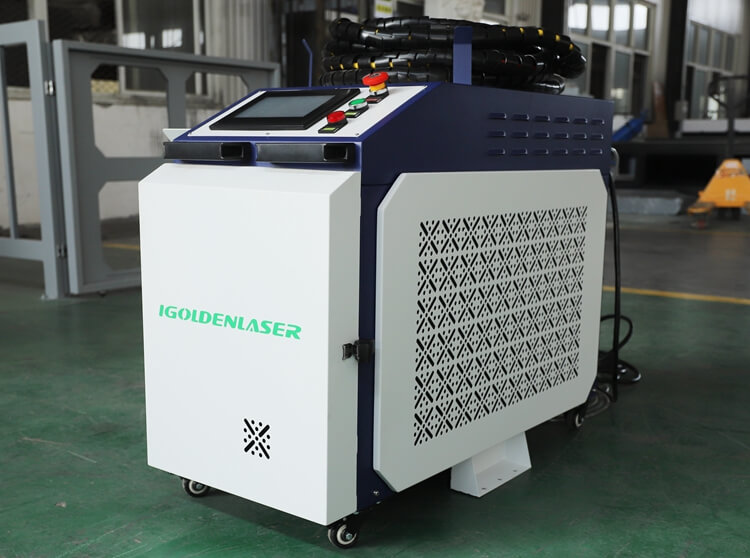

Metal Rust Removal Oxide Painting Coating Removal Laser Cleaning Machine

Laser provides an efficient, cost-effective alternative to conventional technologies for cleaning industrial molds, processing pretreatment, paint stripping, surface preparation. As it can remove rust and other surface coatings without causing damage to the underlying metal. Laser rust removal machines are commonly used in manufacturing, automotive, and shipbuilding industries, where rust and corrosion can cause significant problems.Metal rust removal and oxide painting coating removal laser cleaning machines can be used on a wide range of metals, including steel, aluminum, copper, brass, and more. They are commonly employed in industries such as automotive, aerospace, marine, manufacturing, and restoration.

Laser cleaning is considered an environmentally friendly method compared to traditional cleaning techniques that involve chemicals or abrasive materials. It eliminates the need for harsh chemicals and reduces waste generation, making it a cleaner and greener option.

Fiber Laser Rust Remover for Metal Rust Paint Oil Dirt Stains Coating Removing

Hand-held fiber laser cleaning machine are innovative tools used for rust removal and surface cleaning. They utilize fiber laser technology to remove rust, oxides, contaminants, and coatings from various surfaces without harsh chemicals or abrasives. This handheld laser rust removal machine is commonly used in industries such as mechanical parts manufacturing, automotive, construction, and restoration of cultural relics.

1. Portability: These machines are designed to be compact and lightweight, allowing for easy maneuverability and operation in tight spaces or on irregularly shaped surfaces.

2. Precision: Fiber lasers offer high precision and control, allowing for selective cleaning without damaging the underlying material. This makes them ideal for delicate or sensitive surfaces.

3. Versatility: Hand-held fiber laser cleaning machines can be used on a wide range of materials, including metal, plastic, ceramics, composites, and more. They are effective for rust removal, paint stripping, degreasing, and surface preparation.

4. Non-contact cleaning: The laser beam ablates the contaminants from the surface without physically touching it, minimizing the risk of scratches, wear, or damage commonly associated with traditional cleaning methods.

5. Environmentally friendly: Unlike chemical cleaning processes, fiber laser cleaning is an environmentally friendly solution as it does not generate hazardous waste or pollutants.

6. Efficiency and speed: Fiber laser cleaning is a fast process that can remove rust and contaminants efficiently, increasing productivity and reducing downtime.

7. User-friendly operation: Hand-held fiber laser cleaning machines are typically equipped with user-friendly interfaces and controls, making them easy to operate and adjust for different cleaning requirements.

8.Automation and Integration: Laser cleaning machines can be integrated into automated systems or used in conjunction with robotics for efficient and consistent cleaning operations. This enables high productivity and repeatability, especially for large-scale or repetitive tasks.

Features of Handheld Fiber Laser Rust Removal System:

Wide material applicability, flexible and efficient apply in various industrial scenarios.

Handheld laser cleaning head, light and easy to use, can be used for long-time operation.

With universal casters and easy to move and install.

No need chemical detergent, no consumable, no damage and pollution.

High cleaning efficiency, time-saving.

Stable laser cleaning system, free maintenance.

Advantages of Rust Removal Head:

Scanning width: cleaning head scanning track width, 0.01 ~ 170.00mm (F500 field lens)

Scanning speed: cleaning head scanning track speed, 0 ~ 30,000mm/s

Power: laser output power 0 ~ 100%

High Integration

Highly integrated with two-dimensional scanning mirrors, optical lens components, cleaning control card, software, and human-machine interface, the system is stable, reliable, compact in structure, precise in optical path, good in sealing, exquisite in appearance, lightweight, and easy to install. Only the laser needs to be installed in the gun body and connected to the power supply for use.High Efficiency

Using high-speed motors, the cleaning efficiency is high.High Safety

It has multiple safety mechanisms, including fingerprint and password login, temperature protection, motor abnormal protection, and dropout protection, along with an idle automatic sleep function.Long Distance

The cable can extend up to 30 meters, solving the problem of long-distance operations.

Industry Applications:

Fiber laser cleaning rust removal machine for sheet metal cabinets, iron, aluminum alloy and other hardware industries. Laser cleaning machine can remove the surface resin, the paint, the oil, stains, rust, and oxide coatings. Laser rust removal system has the characteristics of no grinding, non-contact, no thermal effect, suitable for cleaning objects of various materials, etc., and can solve problems that cannot be solved by traditional cleaning methods.

1. Industrial Manufacturing: In manufacturing processes, metal surfaces often accumulate rust, oxide layers, or coatings that need to be removed before further processing. Hand-held fiber laser rust removal machines offer a quick and efficient way to clean rust from metal components, such as pipes, machinery parts, tools, and equipment, without damaging the underlying material.

2. Automotive Industry: Rust is a common problem in the automotive industry, especially in older vehicles or those exposed to harsh weather conditions. Hand-held fiber laser rust removal machines can be used to clean rust from car bodies, chassis, wheels, and other metal parts. This helps in restoring the appearance and structural integrity of the vehicle.

3. Shipbuilding and Maritime: Ships and marine equipment are often exposed to corrosive saltwater environments, leading to rust formation. Hand-held fiber laser rust removal machines can effectively remove rust from ship hulls, decks, propellers, and other metal surfaces, ensuring better performance, longevity, and aesthetics.

4. Aerospace and Aviation: Aircraft components, including fuselages, wings, and engine parts, require regular maintenance and surface cleaning. Hand-held fiber laser rust removal machines provide a precise and non-abrasive method to remove rust and prepare metal surfaces for further treatment or inspections in the aerospace industry.

5. Restoration and Preservation: Cultural heritage sites, monuments, sculptures, and antique artifacts often suffer from rust and corrosion. Hand-held fiber laser rust removal machines offer a delicate and controlled approach to remove rust from these surfaces without causing damage, enabling restoration and preservation efforts.

6. Construction and Infrastructure: Metal structures, such as bridges, railings, pipelines, and building facades, can develop rust over time due to exposure to the elements. Hand-held fiber laser rust removal machines can efficiently clean and restore these structures, improving their durability, aesthetics, and safety.

7. Welding and Surface Preparation: Before welding or applying protective coatings, metal surfaces need to be cleaned and prepared. Hand-held fiber laser rust removal machines can effectively remove rust, paint, and other contaminants, providing a clean surface for welding or coating applications, ensuring better adhesion and quality.

It’s important to note that the effectiveness of a metal rust removal and oxide painting coating removal laser cleaning machine may vary depending on the specific type and condition of the rust, oxide, or coating, as well as the properties of the metal substrate.